Cooled Caster II: Difference between revisions

From Captain of Industry Wiki

Thadius856 (talk | contribs) m typo |

Thadius856 (talk | contribs) fix research |

||

| Line 15: | Line 15: | ||

| Maintenance = None | | Maintenance = None | ||

| Footprint = 7x5 | | Footprint = 7x5 | ||

| Research = | | Research = Advanced Smelting | ||

| Designation = Metallurgy & Smelting | | Designation = Metallurgy & Smelting | ||

| Variants = [[Cooled Caster]] | | Variants = [[Cooled Caster]] | ||

Revision as of 16:39, 18 January 2022

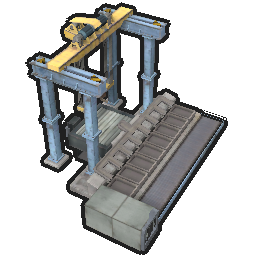

Casts molten materials into slabs. This one also utilizes water for cooling to speed up the process.

| Construction | |

| Workers | |

| Electricity | None |

| Maintenance | None |

| Footprint | 7x5 |

| Required Research | Advanced Smelting |

| Designation | Metallurgy & Smelting |

| Variants | Cooled Caster |

The Cooled Caster II is a direct upgrade of the is the Cooled Caster machine. It features an identical footprint, input/output locations, and recipe ratios with the only difference being a higher overall throughput. Visually the machine is identical to its predecessor with the exception of the crane supports and built-in conveyor belt being yellow.